Diesel Exhaust Fluid (DEF) Quantity Test For Detroit Diesel

Detroit Diesel EPA 2010 and newer engines will often have active and inactive codes for the DEF system. There are a variety of Detroit DEF and SCR tests that exists, which we want to make you aware of. The following is a shortlist of possible codes that you could see:

- SPN 3361 FMI 0

- SPN 3361 FMI 1

- SPN 3361 FMI 3

- SPN 3361 FMI 4

- SPN 3361 FMI 5

- SPN 3361 FMI 7

- SPN 3361 FMI 8

- SPN 3361 FMI 31

- SPN 3364 FMI 1

- SPN 3364 FMI 2

- SPN 3364 FMI 17

- SPN 3364 FMI 18

- SPN 4364 FMI 1

- SPN 4364 FMI 18

- SPN 5246 FMI 0

- SPN 5246 SPN 15

- SPN 5246 SPN 16

No matter which code you have, the troubleshooting steps are all very similar.

Troubleshooting The Detroit Diesel DEF Codes

Basic DEF Checks First

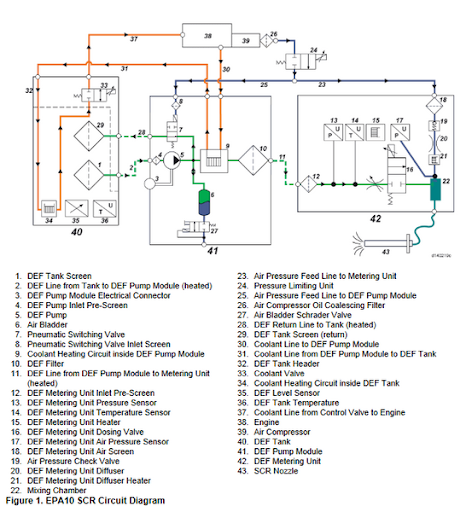

The first two steps are fairly easy. First, check the DEF supply and airlines. You are looking for any leaks, kinks, cracks, or disconnected lines. The next step is to compare the DEF pressure and the DEF Air pressure to the ambient air pressure, better known as the barometric pressure. If they are within 4 PSI of the ambient air pressure, they are reading correctly. If 4 PSI or higher, then you need to fix the DEF pressure and/or the DEF air pressure sensors.

Detroit Diesel SCR Air Pressure Test

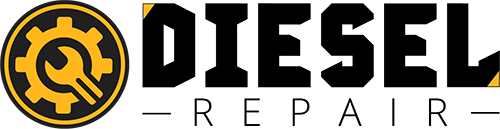

This step requires that you own a computer-based diagnostic tool to run this command. Both the Detroit Diesel Diagnostic Link software and the TEXA Dealer Level Tool can perform these commands. What you do first is disconnect the Detroit DEF tank return line from the DEF pump. You then run the “SCR Air Pressure Test”, which runs for about 60 seconds. What you are looking for is to see if the DEF fluid comes out of the pump return outlet during the test procedure. If it does, you need to replace the DEF Pump Pneumatic switching valve. If it does not, we proceed to the next step.

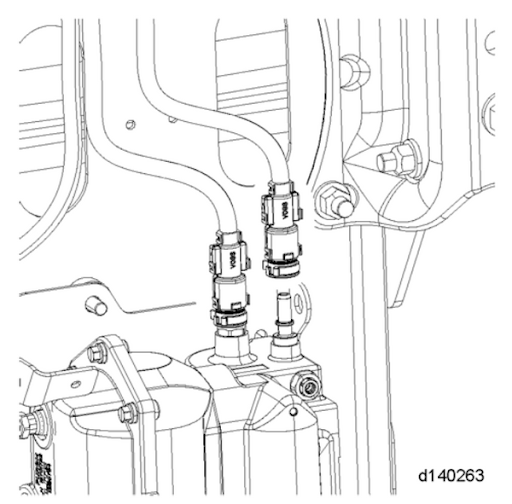

Detroit Diesel DEF Metering Unit

In this step, we are going to use the same command as before, the SCR Air Pressure Test. To perform this test, you disconnect the DEF aerosol outlet line from the DEF Metering Unit. As you run the command, you are watching the DEF aerosol line outlet on the metering unit. If there is DEF fluid coming out, you need to replace the entire DEF Metering Unit. If not, reconnect the aerosol line and proceed to the next step.

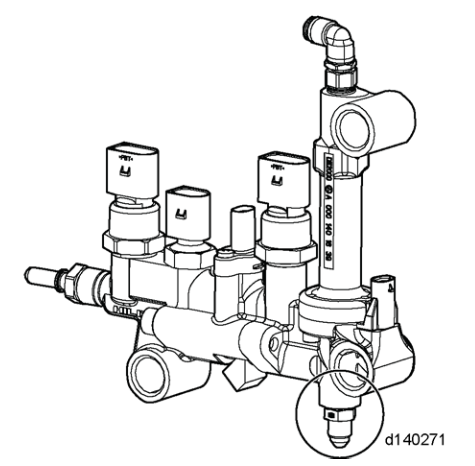

Detroit Diesel DEF Pump Module Air Bladder

If you haven’t found any leaking components yet, we must now test the DEF pump module air bladder. The first part of this test is to deflate the air bladder completely. You then need to regulate your shop air pressure to 55 PSI and re-inflate the air bladder to 40-46 PSI through the Schrader valve as shown in the image to the right. At this point, you would go back to your diagnostic tool and run the “DEF Quantity Test” next.

Detroit DEF Quantity Test

The Detroit DEF Quantity Test is a command that is run with our diagnostic software. This test will measure how much DEF fluid is dispensed, which then tells you if the DEF Nozzle is functioning properly or not. In order for this command to run properly, the following criteria must be met:

- Over 100 PSI in the air tanks

- Ambient air temperature over 0 degrees Fahrenheit

- DEF temperature over 14 degrees Fahrenheit

- DEF tank temperature over 21 degrees Fahrenheit

Once those criteria are met, you would remove the DEF nozzle from the after-treatment device and place it in a beaker. You then run the command and see how many milliliters are dispensed. You are wanting between 108 mL and 132 mL (3.7 oz to 4.5 oz). If you are outside this range, you need to replace the Detroit DEF Dosing Unit.

SCR Self Check Route

The Detroit Selective Catalytic Reduction (SCR) Airless Dosing Systems (ADS) Self-Check routine is the next step. Again, you will need either the Detroit Diesel Diagnostic Link software or a tool such as the TEXA Truck in order to perform these commands. You simply run the SCR ADS Self-Check Routine, and you are looking at the following parameters to be within specifications:

- DEF Pump Speed between 750 RPM and 1800 RPM

- DEF Pressure between 900 mbar and 1100 mbar (130 psi to 160 psi)

If you are within those specifications, continue to the next step. If you are not, Detroit requests that you contact their call center at 800-445-1980 for further instructions.

Perform a DPF Regen

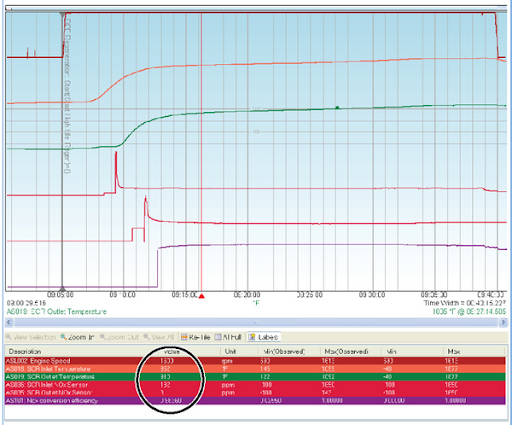

If you still have not found any issues at this point, the next step is to perform a Diesel Particulate Filter (DPF) Regeneration using a diagnostic tool. Again, as in previous steps, you will need a computer-based diagnostic tool to do this. When performing this test, we want to monitor Engine Speed, SCR Inlet Temperature, SCR Outlet Temperature, SCR Inlet NOx Sensor, SCR Outlet NOx sensor, and NOx Conversion Efficiency. Once the regen command starts, you want to monitor the NOx conversion efficiency. It should rise and stay above 85%. If it does and the regen completes with no additional fault codes, the truck is completed and should be released to the customer. If it does not, Detroit Diesel asks that you contact them at 800-445-1980.

Need More Repair Info? Check out our Diesel Repair platform to have free access to quality repair information today!

Click here to sign up for free!